Manager Dashboards

Provides live and historic data on day-to-day manufacturing operations.

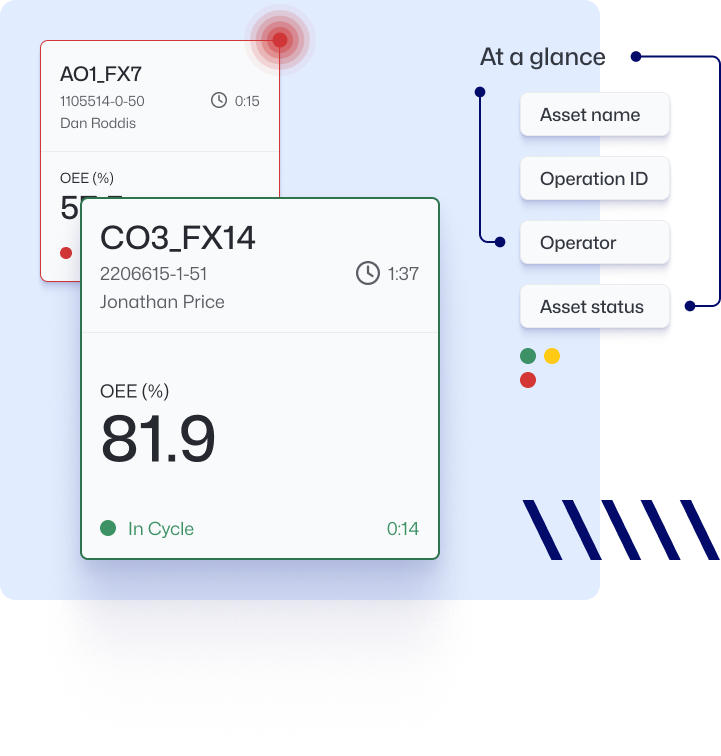

Factory Viewer

- Visualise data for every asset on your shop floor.

Prioritise Metrics that Drive Value

Analyse daily OEE for assets, or track trends over the week.

Customise Asset view

Filter asset data by name or type.

Enhance Operational Efficiency

View the status of any asset at a glance, helping you plan resources more effectively.

Production Overview

- Gain a comprehensive view of production data at all levels.

Aggregate Data across Levels

View production data at both global, regional, factory and asset levels.

Interrogate Critical Metrics

Evaluate throughput, performance and OEE across entire production flows to identify areas for improvement.

Navigate with Ease

Utilise advanced data visualisations, extensive filtering and sorting capabilities.

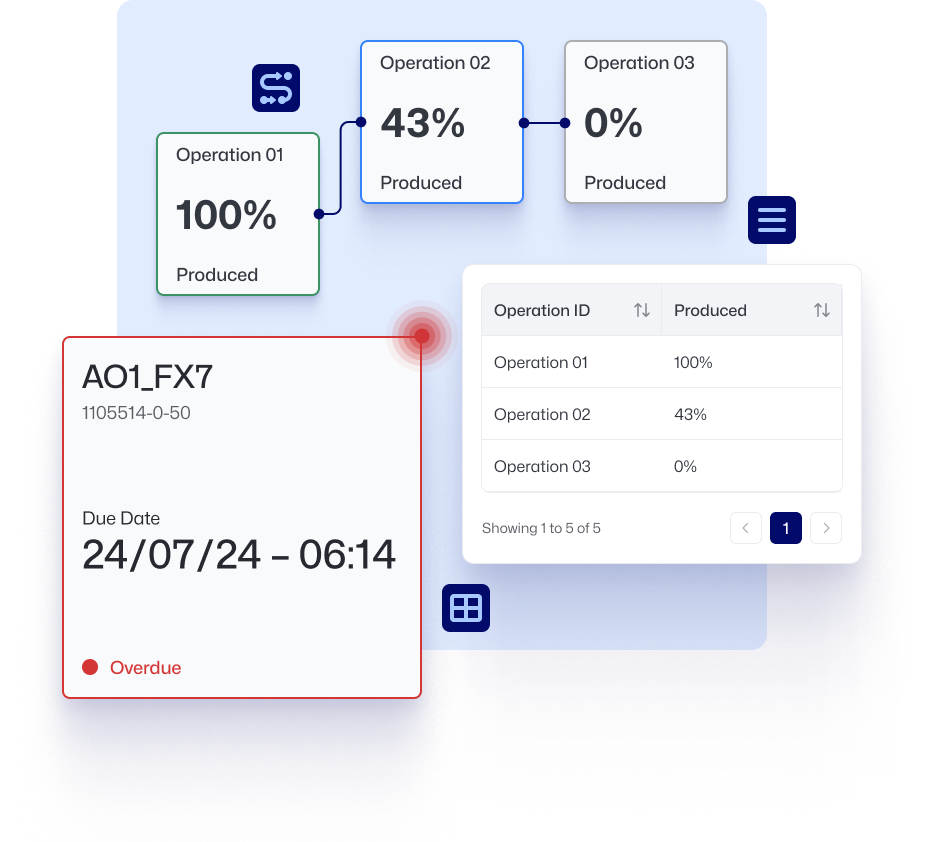

Process Flow

- Instantly view and manage order progress.

Manage Operation queues Efficiently

Gain immediate insights into part runs and quantity produced.

Predict order timelines

Utilise historical OEE data to forecast whether orders will be completed on time or become overdue.

Streamline Order tracking

Integrate with ERP, PLM and MES systems to track current orders and quantities needed.

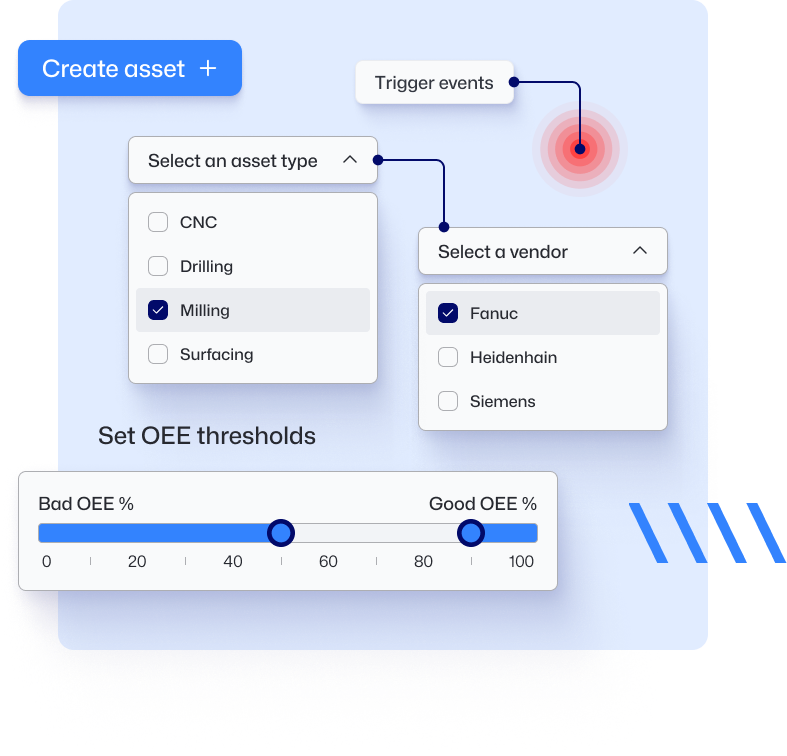

Asset Management

- Create and manage assets.

Asset Onboarding

Add asset details such as asset type, vendor details and other essential information.

Customisable thresholds

Define parameters to analyse OEE across assets according to your preferences.

Configurable Asset Signals

Implement PLC and sensor data to create alarms and signals for productivity.

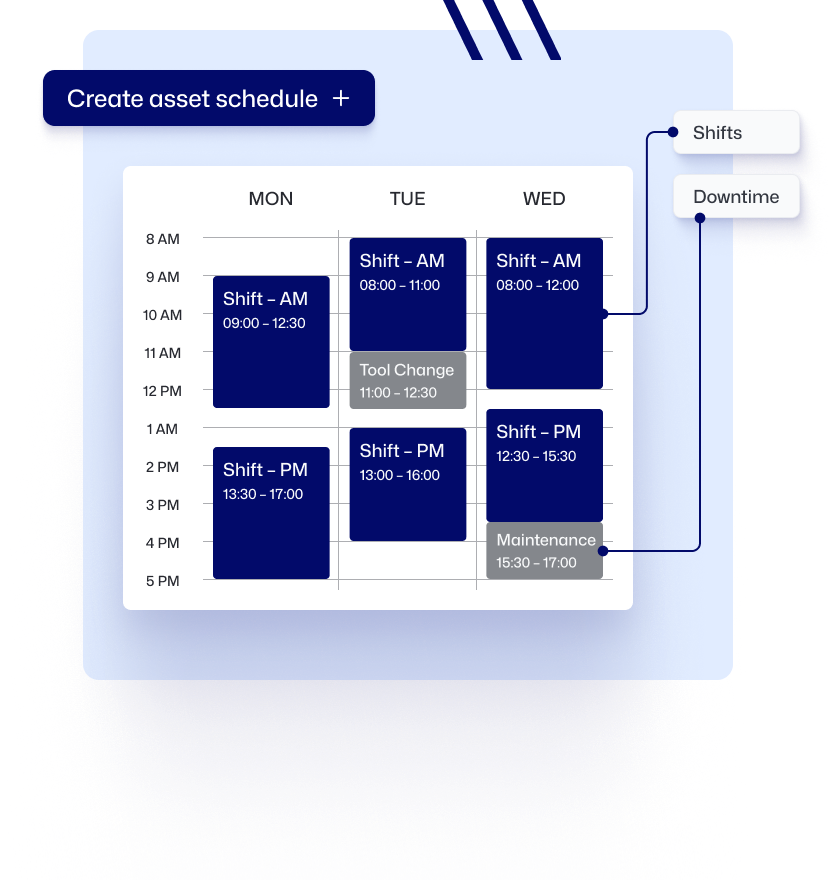

Schedules & Events

- Ensure machine schedules are visible and managed for peak performance.

Schedule configuration

Create and assign operating schedules to assets to accurately oversee operational capacity.

Event Creation

Create and categorise operational events.

Automate triggers

Set manual or automatic triggers for downtime and other operational events.

Get in touch to talk about your challenges.

There is no one-size-fits-all approach to digital manufacturing. We standardise the parts that make sense and configure the rest to you.

hello@razor.co.uk +44 114 312 2058Produced by