Operator Dashboards

Sitting on a screen at every machine, MIP streamlines both data entry and reporting.

Job Configuration

- Seamlessly setup jobs for the operation queue.

Streamline Operations

Start and end jobs with ease, collect run times accurately and monitor order progress.

Track Operation Queues

Efficiently monitor part count against operation queues.

Boost planning

View key data on asset jobs, including an estimated job finish time derived from historical OEE data.

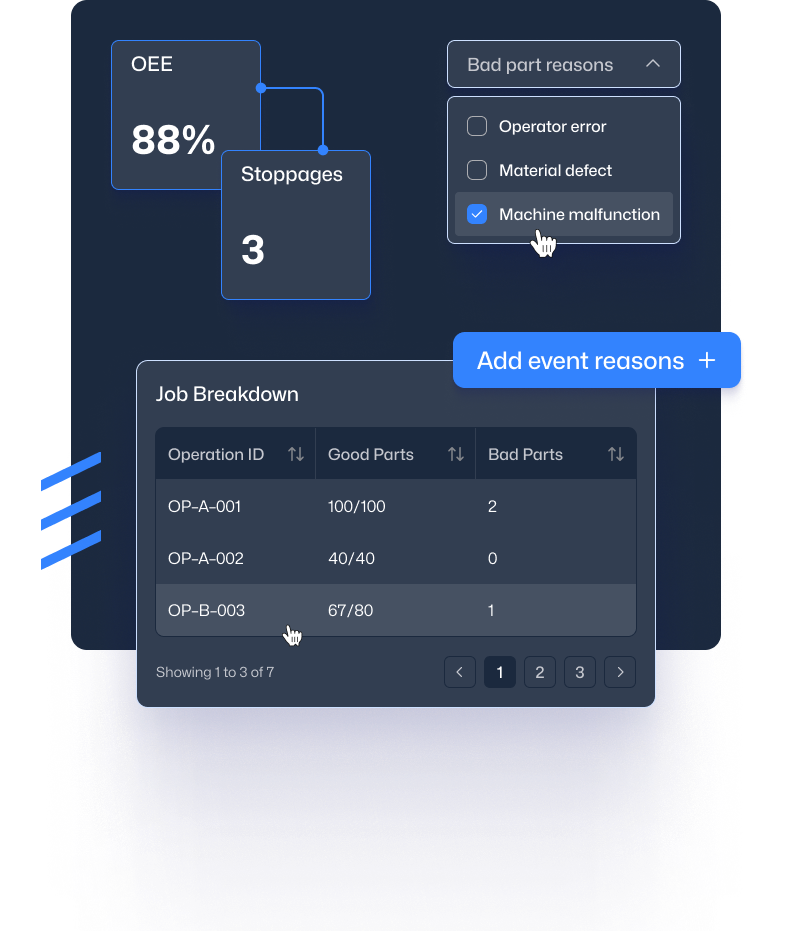

Active Job Monitoring

- Capture, manage and access real-time and historical operational data.

Oversee Part Management

Automatically capture part count, assign conforming and non-conforming conditions and record additional context for each defect.

Simplify Data Input

Enable operators to swiftly record event causes and operational details, enabling focused task execution.

Gain Actionable Insights

Access critical data such as Overall Equipment Efficiency (OEE), empowering operators to refine their processes and make informed decisions.

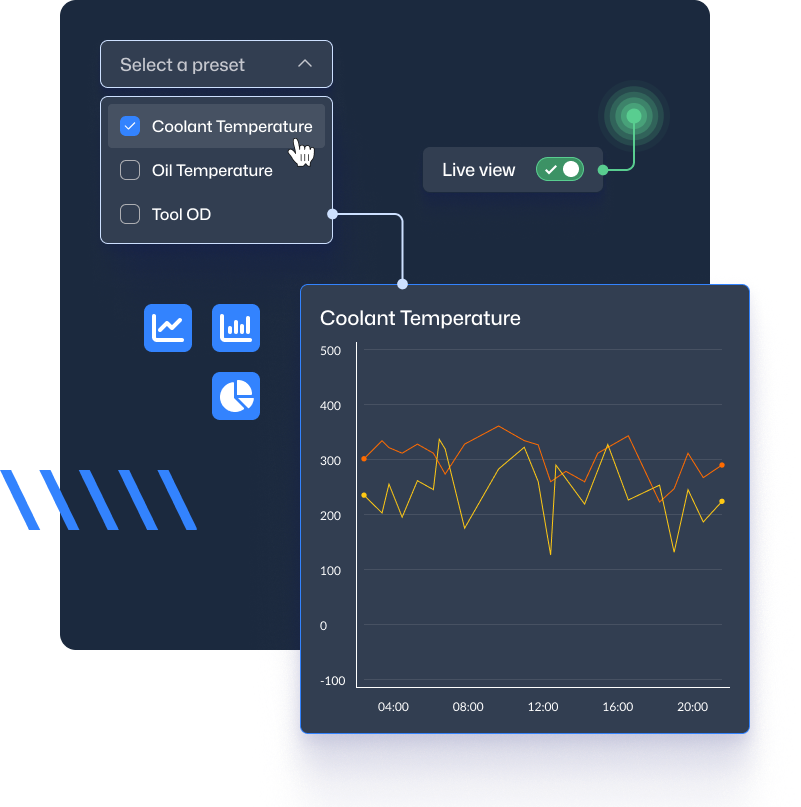

Process Monitoring

- Measure the heartbeat of your Manufacturing Processes.

Real Time Data

View the live performance of machines and extract key insight into their performance.

Monitor What Matters

Configure visualisations to display the data points that matter most to you.

Health Monitoring

Uncover key trends to understand the health of your machines and identify quickly when something is going wrong.

Get in touch to talk about your challenges.

There is no one-size-fits-all approach to digital manufacturing. We standardise the parts that make sense and configure the rest to you.

hello@razor.co.uk +44 114 312 2058Produced by